PARADIM Highlight #54—External User Project (2022)

Ling Jessica Fei (University of Louisiana at Lafayette)

The ever-growing demand for electric vehicles and portable electronic devices continues to drive the craving for lightweight, high-energy-density, and long-lifespan batteries. Currently used lithium-ion batteries are limited by the capacity of the electrode and the scarcity of resources (lithium). The search for next-generation materials not only seeks to replace lithium with sodium but to provide suitable anode materials. Metal selenides (MSe, M = Sn, Fe, Ni, Cu) offer the desired conductivity, stability, cost-effectiveness, and higher theoretical capacity compared to commercial graphite.

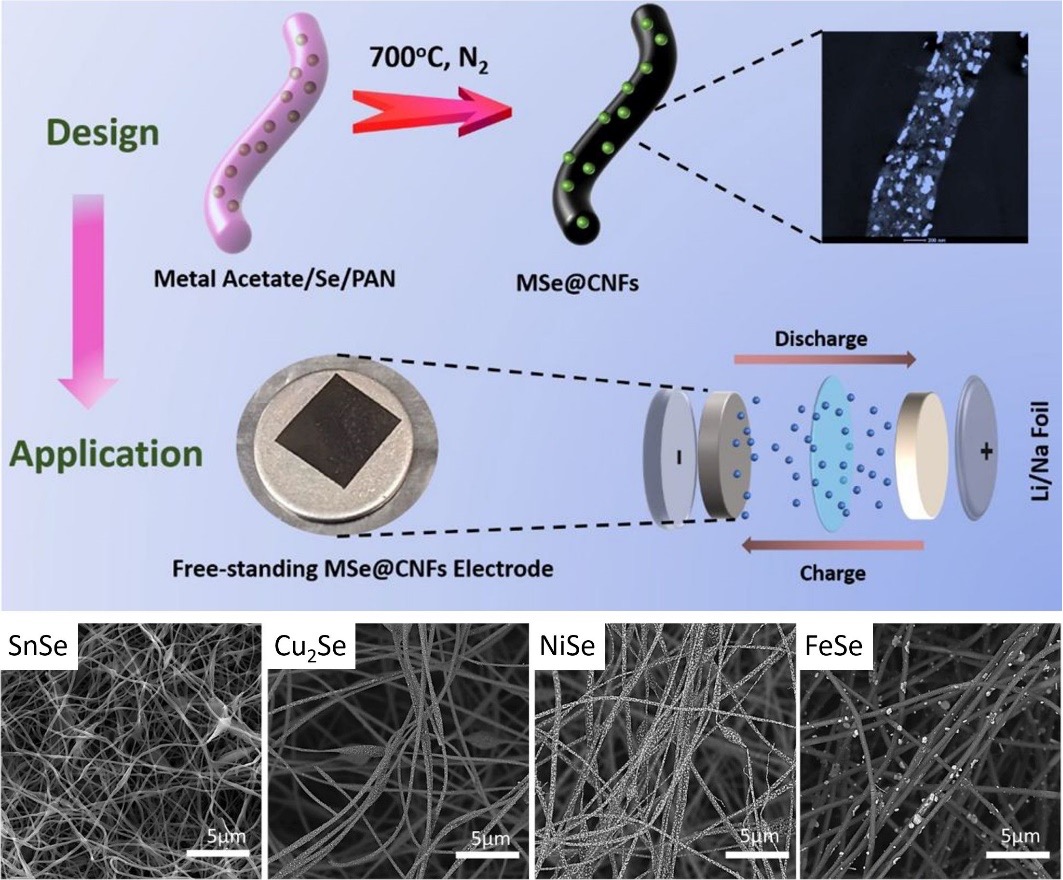

Figure 1: Schematic illustration and SEM images of various MSe@CNFs electrodes.

Combining metal selenide nanoparticles with carbon nanofibers to form a free-standing network enables fast electrolyte penetration, accommodation of volume changes, and electron transport along the fibers. Electrospinning offers a unique single-step approach to produce anodes reliably and reduces weight and contamination from otherwise needed additives. Device performance and cycle stability were investigated.

The morphology and structure of the formed composite materials were analyzed using PARADIM’s electron microscopy facility.

The craving for lighter, smaller, and longer-lasting portable devices has driven researchers to explore next-generation materials for both lithium-ion batteries (LIBs) and sodium-ion batteries (SIBs). Metal selenides are a notable material family that exhibits desirable conductivity, stability, and cost-effectiveness. Moreover, they can provide higher theoretical capacities than that of a commercial graphite anode. In this work, a generalized synthesis strategy is reported to achieve free-standing metal selenides and carbon nanofibers composites (MSe@CNFs) as anodes for LIBs and SIBs by using facile electrospinning. The composites have active nanoparticles embedded in each carbon nanofiber, and the carbon nanofibers intertwine with each other to form a 3D nanofiber network. The structure−property−performance relationship of metal selenides (MSe, M = Sn, Fe, Ni, Cu) embedded in CNFs were thoroughly investigated in the LIBs system. The one-step prepared free-standing anodes show a high specific capacity as well as good rate capability and cycle stability. The good performance is ascribed to the high electron conductivity originating from the N-doped carbon nanofiber network, fast electrolyte penetration through interfiber voids, and accommodation of volume change enabled by the carbon encapsulation of nanoparticles. Additionally, the absence of the binder, additive carbon, and current collector not only reduces the weight of the anode but also eliminates the uncontrollable structure formation from the slurry coating method. Postmortem analysis further confirms the robust structural stability of these rationally designed composites. When the application is extended to SIBs, the composites also demonstrate great potential. In short, free-standing MSe@CNFs composites show great promise for the next generation of flexible and lightweight batteries that are crucial for various emerging applications.

This study shows a generalized method to prepare binderless, free-standing metal selenides and carbon nanofibers composites for lightweight and high-performance batteries. The microstructure characterization reveals that the unique structure is the key to achieving such high performance.

Staff at PARADIM’s Electron Microscopy User Facility provided characterization of the MSe@CNF samples by using a Tescan Mira3 field-emission scanning electron microscope and a FEI F20 field-emission scanning transmission electron microscope operating at 200 kV.

The project was initiated by scientists from the University of Louisiana at Lafayette and the material characterization at PARADIM was made available via a PARADIM user proposal.

Z. He, H. Guo, J.D. LaCoste, D. Werder, D.J. Durocher, R.A. Cook, P. Truong, H. Luo, X.-D. Zhou, and L. Fei, "A Generalized Synthesis Strategy for Binderless, Free-Standing Anode for Lithium/Sodium Ion Battery Comprised of Metal Selenides@Carbon Nanofibers," ACS Appl. Energy Mater. 5, 842-851 (2021). DOI: https://doi.org/10.1021/acsaem.1c03277

L.F. acknowledges financial support from the National Science Foundation (Award Number 1832963) and Chevron Corporation for providing the Chevron Endowed Professorship in Chemical Engineering at UL Lafayette. X.D.Z. and L.F. are thankful for the support from NSF under NSF-2119688 and NASA# 80NSSC21M0333. L.F. also acknowledges facility support from the NSF MRI Program (NSF-1920166). This work also made use of the Cornell Center for Materials Research Facilities supported by the National Science Foundation under Award Number DMR-1719875 and was supported by NSF Platform for the Accelerated Realization, Analysis and Discovery of Interface Materials (PARADIM) under Cooperative Agreement No. 2039380. D.J.D. and R.A.C. acknowledge the support from the UL Lafayette College of Engineering Research Apprentice program.

Data Availability:

Electron Microscopy data generated at PARADIM during this work is available via the PARADIM Data Collective at https://doi.org/10.34863/74cq-cq37.