PARADIM Highlight #93—Local User Project (2024,Paid)

Mitra L. Taheri (JHU), John R. Scully (U. Virginia), and Karl Sieradzki (ASU)

Multi-principal element alloys have the potential to show excellent passivation behavior. Identification of promising compositions often relies on a combinatorial library (CL) alloy wafer approach, but the validity of results from such films in predicting bulk alloy performance is unknown.

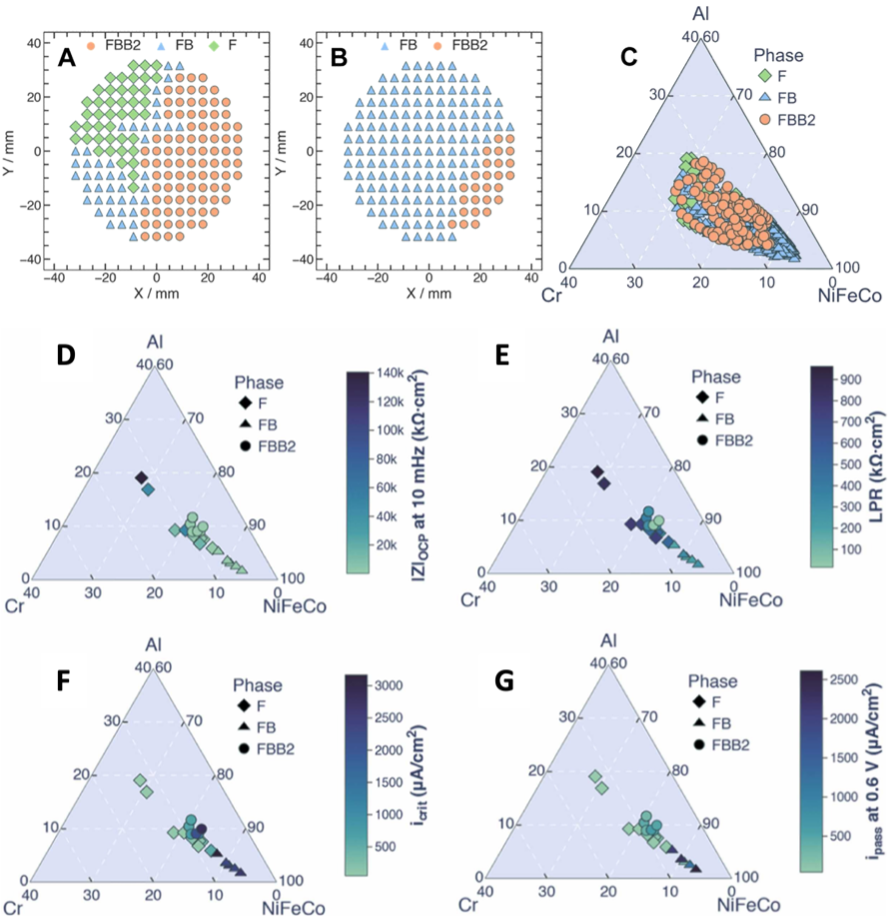

Figure: Compositions and crystal structures of the combinatorial library wafers. (A, B) XRD at each spot on the wafers was measured. (C) Pseudo-ternary phase diagram of all spots as a function of composition. (D-G) Scanning droplet cell results of the aqueous electrochemical measurements on the CL wafers plotted on the pseudo-ternary phase diagrams, |Z|OCP (D), LPR measured after reduction of the air-formed oxide (E), critical current density for passivation (F), passive current density, ipass at 0.6 V (G).

In this work, 177 alloy spots from a CL with varying composition and structure were studied. Bulk samples of (FeCoNi)1-x-yCrxAly were prepared and processed at PARADIM using unique capabilities of its ancillary synthesis facility, including oxygen free arc melting and water jet cutting capabilities to enable quantitative comparisons with the CL spots. Due to varying grain size and the grain boundary dissolution a one-to-one correlation could not be made useful between thin films and bulk. However thin films of varying composition can be compared relative to one another in terms of common passivation metrics (such as Ecorr, icrit, ipass, |Z|, etc.) across a CL wafer and that this trend in behavior can be used to predict the likely best bulk sample composition(s) for passivation performance.

We investigated a combinatorial library alloy wafer approach, containing 177 alloy spots comprised of a range of different compositions and crystal structures. These results demonstrate that significant quantitative differences in passivation metrics exist between bulk and thin-films and that a one-to-one correspondence between thin-film and bulk behavior should not be expected as a result of the different grain sizes and grain boundary dissolution. However, we found that thin-films of varying composition can be compared relative to one another in terms of common passivation metrics (such as Ecorr, icrit, ipass, |Z|, etc.) across a CL wafer and that this trend in behavior can be used to predict the likely best bulk sample composition(s) for passivation performance.

Multi-principal element alloys have the potential to show excellent passivation behavior. However, the detailed compositional and crystal structure design of these alloys requires a high-throughput strategy. We used combinatorial thin-film libraries of single-phase (FeCoNi)1-x-yCrxAly alloys and compared their passivation behaviors to corresponding bulk alloys. Our results demonstrate that the detailed passivation behaviors of thin-films and bulk alloys are different which is related to both nanoscale porosity within the thin-films and grain boundary dissolution. Nevertheless, we found that comparisons made among suitably designed sets of thin-film alloys can be used to determine the best corrosion performing bulk alloy composition.

As paid use between external users, bulk samples were prepared to form a set of bulk (FeCoNi)1-x-yCrxAly samples and subjected to homogenization and aging treatments using unique equipment in the ancillary synthesis facility. From projects like this one, we have learned both the strengths and weaknesses of a paid-use model for the continuation of the MIPs.

W.H. Blades, D. Sur, H. Joress, B. DeCost, E.F. Holcombe, B. Redemann, T.M. McQueen, R. Berlia, J. Rajagopalan, M.L. Taheri, J.R. Scully, and K. Sieradzki, “High-Throughput Aqueous Passivation Behavior of Thin-Film Versus Bulk Multi-Principal Element Alloys in Sulfuric Acid,” Corros. Sci. 236, 112261 (2024). DOI: https://doi.org/10.1016/j.corsci.2024.112261

The authors gratefully acknowledge partial funding from the Office of Naval Research (ONR) through the Multidisciplinary University Research Initiative (MURI) program, N00014-20-1-2368. The authors also acknowledge the University of Virginia Nanoscale Materials Characterization Facility, the Eyring Materials Center at Arizona State University, and the Johns Hopkins University Materials Characterization and Processing Center. J. Rajagopalan acknowledges support from the National Science Foundation Grant 2223317 (Metals and Metallic Nanostructures program). Use of the Stanford Synchrotron Radiation Lightsource, SLAC National Accelerator Laboratory, is supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences under Contract no. DE-AC02-76SF00515. Materials processing was performed at the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM at JHU), a National Science Foundation Materials Innovation Platform under Grant no. NSF DMR-2039380. The authors thank J. Hattrick-Simpers (University of Toronto) for his assistance in carrying out these experiments and A Mehta (SLAC), N Johnson (SLAC), and N Patra (SLAC) for collecting the synchrotron diffraction data.